Emergency towing-off pennant, commonly known as “fire wire,” is a long wire deployed on the sea side of a tanker ship berthed in a terminal.

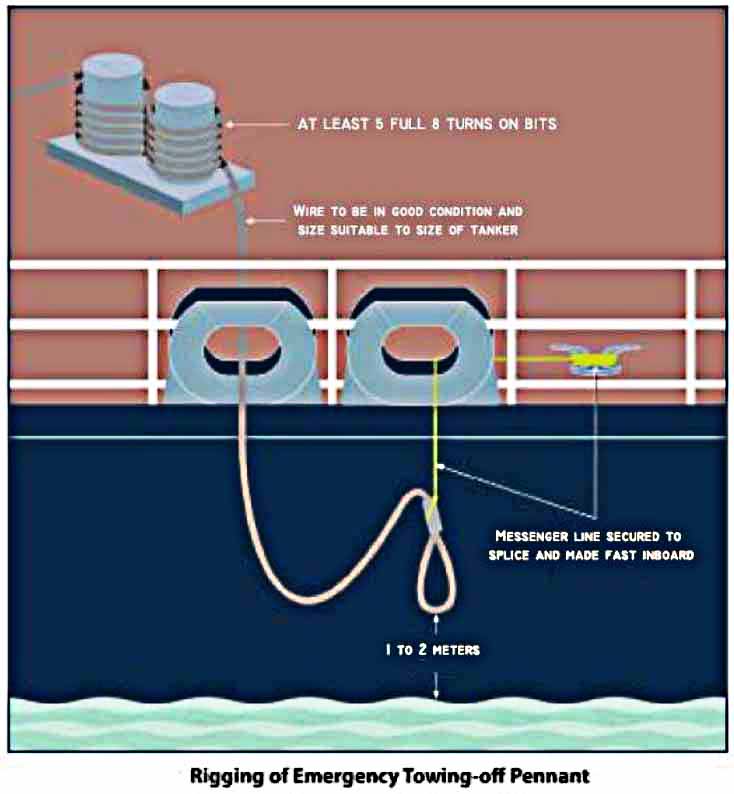

Its one end is firmly secured on the bitts while its eye on the other end is hanging one to two meters above the water line.

Ships use fire wires specifically during an emergency.

In the event that the terminal or the ship itself catches fire, tugboats use these wires to pull the ship away thus minimizing the extent of the damage.

That’s the theory. In reality, there are actually more injuries associated with fire wires than their intended purpose.

Before we tackle that, let us discuss the correct way of deploying emergency towing-off pennants.

Fire wire standards

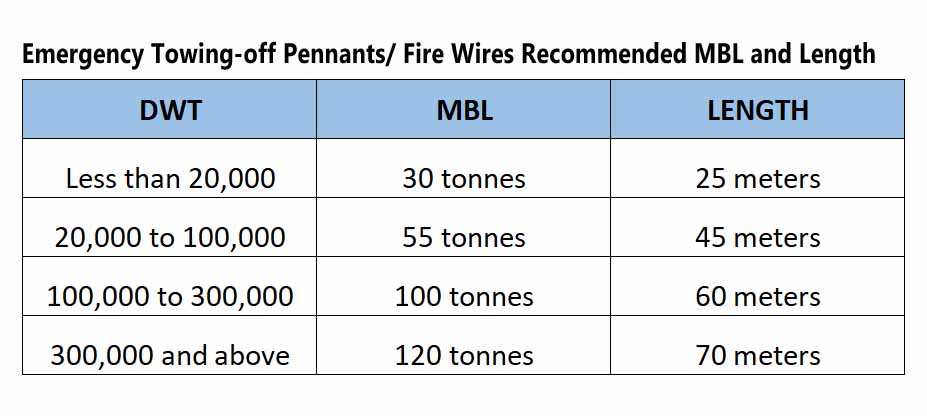

Using the right length and size of emergency towing-off pennants depends on the deadweight tonnage of the ship as well as the position of the securing bitts.

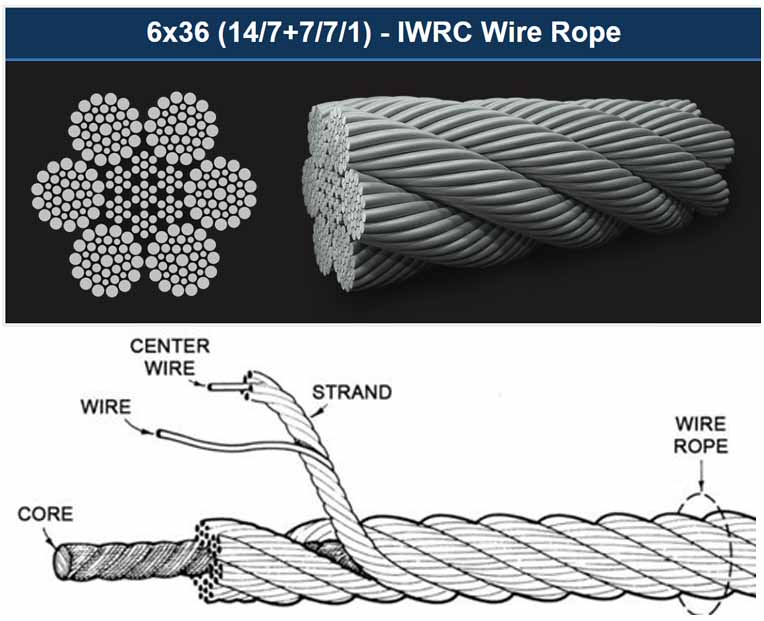

As per the “Mooring Equipment Guidelines”, fire wires should have a 6 x 36 IWRC construction.

In simple terms, this means that the wire rope must have six strands with each strand having 6 wires coiled around it.

Furthermore, it must have an independent wire rope core hence the IWRC standard.

In short, fire wires must be of the same material as your regular mooring wire.

Current synthetic and fiber ropes are not feasible since they will burn during intense heat and fire.

Rigging Fire Wires

Most types of merchant vessels rig emergency towing-off pennants on the offshore side especially tankers.

In cases where the ship moors to the buoys, you should deploy them on the side opposite the hose or manifold connection.

There are three main points that seafarers must consider in rigging fire wires.

First is its length in relation to the distance of the eye on the water line. Deck watchkeepers must check that the eye is within one to two meters above the water line.

If the eye is too high, tugboats may not be able to reach it or secure it in their hook. Too long and the eye or the line itself may be underwater. Tugboats will find this difficult to pick up during an emergency.

Second is the securing end.

While one end is on the offshore side of the ship, you must secure the other end on the bitts. Particularly, you must fasten it in a figure-of-eight manner of at least five turns.

The securing bitt must have a safe working load (SWL) of not less than that of the wire’s MBL or minimum breaking load.

Third is the messenger line and the slack on deck.

When rigging the emergency towing-off pennants, the wire should not have any slack on deck.

So from the bollard, the eye should pass through the chock. Then secure it with a messenger line attached to the splice to give the wire enough slack and prevent it from touching the water.

As the ship’s draft changes when ballasting or deballasting and discharging or loading operation, the distance of the fire wire against the water line changes.

You must adjust the messenger line to maintain the required one to two-meter gap.

Ideal situation where fire wires are useful

Imagine you are in a tanker vessel loading gasoline in a certain port. After mooring the ship safely alongside, you rigged the fire wires as per the ship-shore safety checklist.

A few hours later, you commenced loading gasoline and everything went well. During the middle of your operation, you hear an alarm from the terminal and see one of its tanks.

You alerted the CCR and the loading operation stopped. The captain also sounded the general alarm and before you knew it, there were already tugboats on the forward and aft parts of the vessel.

They took the fire wires and since your mooring ropes are still tied to the terminal, they can’t do anything other than wait.

With the help of emergency disconnection of the loading arm, what’s keeping you waiting are the mooring ropes.

As soon as you arrived at the mooring stations, you took the fire axe and hacked the ropes after seeing that nobody was on the shore to release them.

The fire also started getting big so why not cut your losses on these ropes to save the ship and her crew?

After that, the tugboats pulled the vessel away from the burning terminal using the fire wires.

Nobody got hurt and the ship escaped from greater danger.

Usefulness Review

Like our example above, the main idea why tanker ships rig fire wires on the off-shore side of the vessel is to tow them away from the terminal as quickly as possible without crew intervention using tugboats.

This sounds good and realistic considering that vessels usually shut their main engines while berthed alongside.

However, these are only “what ifs” and in practice, fire wires brought more harm than their intended good.

As a matter of fact, the OCIMF does not recommend using them.

During a study of its 33 million deployments on tanker ships of various sizes, there was not a single instance where fire wires were used in an emergency.

This is profound considering that when we conduct a risk assessment, we can not quantify the likelihood of something happening in this context.

Furthermore, there are approximately 1,700 crewmen injured while handling fire wires over the past 42 years!

However, due to terminal regulations and the support from ISGOTT’s ship-shore safety checklist, we are still rigging fire wires to this day.

My personal experience with fire wires

They are rigid and very heavy!

I have been rigging and securing fire wires since my first tanker days and they are all the same- very heavy, rigid, and dangerous.

Since some of my vessels only have three fire wires- one forward and two aft, this is where it becomes more troublesome.

If we secured the emergency towing-off pennant on the starboard side and the next port is also on the starboard side alongside, we have to transfer them to the port side because that is where the off-shore side is.

Transferring means uncoiling them on the current bitt and pulling them up to the other side.

Then, we have to re-coil one end to the bitt and tie them up to keep them fully secured. After that, we can deploy the other end to the ship’s side.

This job needs at least three men to accomplish. Two men could do it but it would be very difficult as these wires are very long, very heavy, and very stiff.

That’s where back pains and injuries come in.

How I minimized handling fire wires

Over time, I learned to “maneuver” when to rig and not to rig them. Since not all ports require the deployment of fire wires, I often talk to the officers if the terminal requires them.

If not, then we just saved our crew from potential injury. But if they want it, it’s still okay as long as we lessen the frequency.

A good way to know if you need fire wires in a particular port is to look at other tanker ships or any vessel docked around the terminals.

If most of them have emergency towing-off pennants deployed, there’s a good chance that you will also have to. If not, then it’s probably not required.

May the winds be in your favor.

0 Comments