Rudders are an important part of a ship. They are installed on small motor boats to the biggest watercraft ever to sail the seas.

It is a crucial component of the vessel’s steering system and the whole ship as well.

A vessel could be burning or facing a heavy storm but as long as their engines and rudder are working well, they have a good chance of survival.

What is a Rudder?

A rudder is a blade-like component located in the submerged aft section of a vessel, responsible for providing directional control.

This is achieved by deviating water flow as effectively as possible in combination with minimum resistance.

In order for ships to get to their destinations, they must be able to follow their planned route despite the forces of winds, waves, currents, and swell.

Rudders make this possible even in today’s highly complicated steering system.

A rudder’s area ranges from 1.5% to 10% of the underwater lateral area of a ship. Yes, it’s that small.

How Does a Rudder Work?

A rudder works by utilizing and directing the flow of water around the hull to steer the ship.

For the rudder to steer the ship, we must first discuss two important forces acting on a vessel.

They are the Pivot Point and the Flow of Water.

These two will help us understand how rudder works and why shipbuilders position them aft.

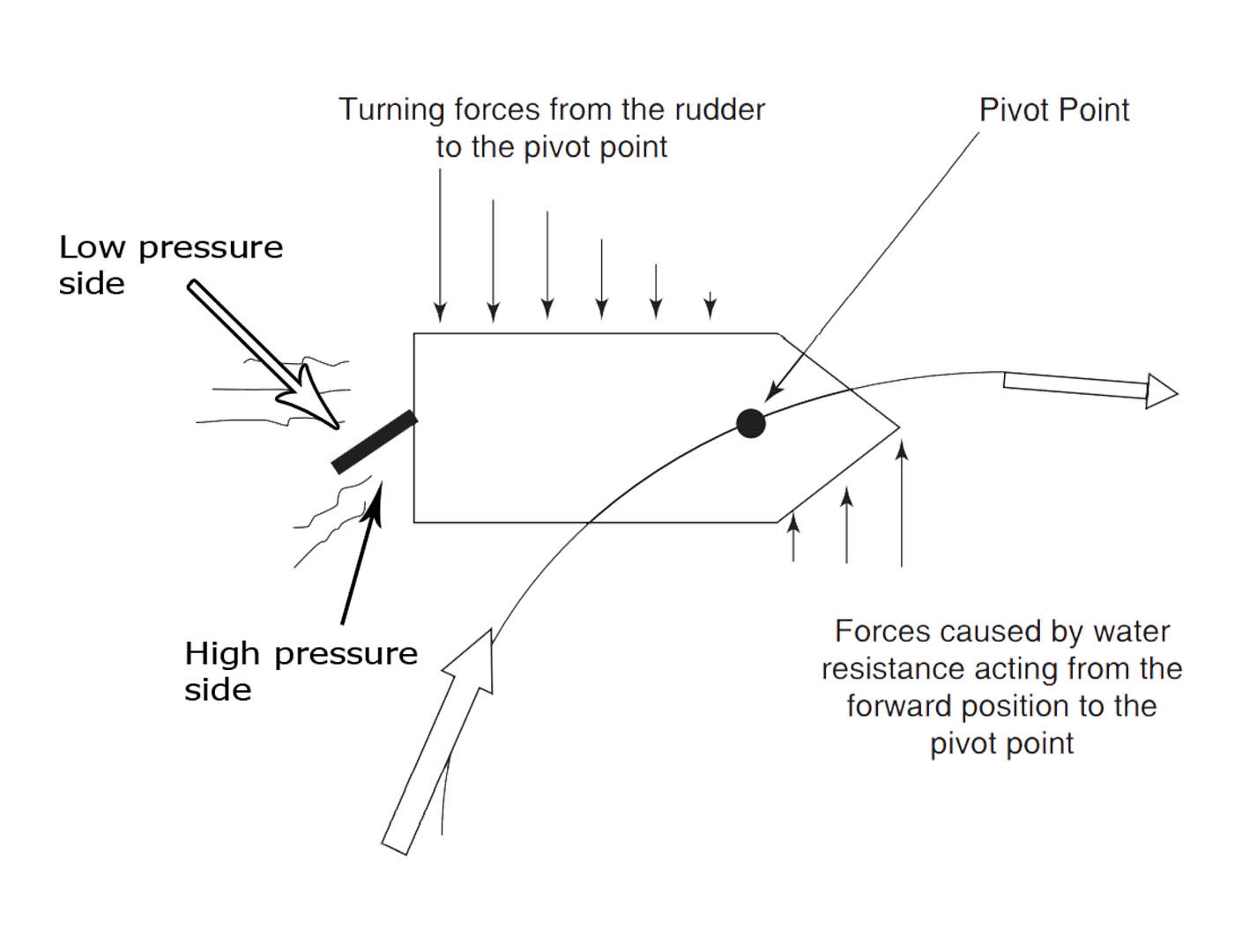

Pivot Point

A pivot point is an imaginary spot on a ship where the vessel “turns” when moving, maneuvering, or altering course.

Think of it like the point where the seesaw is fixed, but on ships, this point is unstable depending on the vessel’s movement.

A vessel stationary on the water has its pivot point located in the middle of the ship. When it starts to move astern, this point also moves aft.

When the vessel moves forward, the pivot point also moves forward.

The faster the speed, the further this point moves in that direction.

Installing the rudder aft creates maximum lift or turning power since the pivot point goes forward when the vessel moves ahead.

Flow of Water

The second force is the flow of water.

A rudder angle parallel to the stream creates neutral force thereby doing nothing to the vessel.

But when you turn the rudder to a certain angle, it creates a high and low pressure on the two sides of the rudder blade.

Pressure Imbalance

High water pressure is present on the side where it is directly hit by the water flow. Inversely, the other section has low pressure.

Due to this imbalance, the stern turns to the low-pressure side of the rudder to equalize the unbalanced forces.

The stronger the flow, the greater the imbalance. Thus, the pressure difference between the two sides is also high leading to faster vessel response.

This is the reason why shipbuilders position the rudders just behind the propeller.

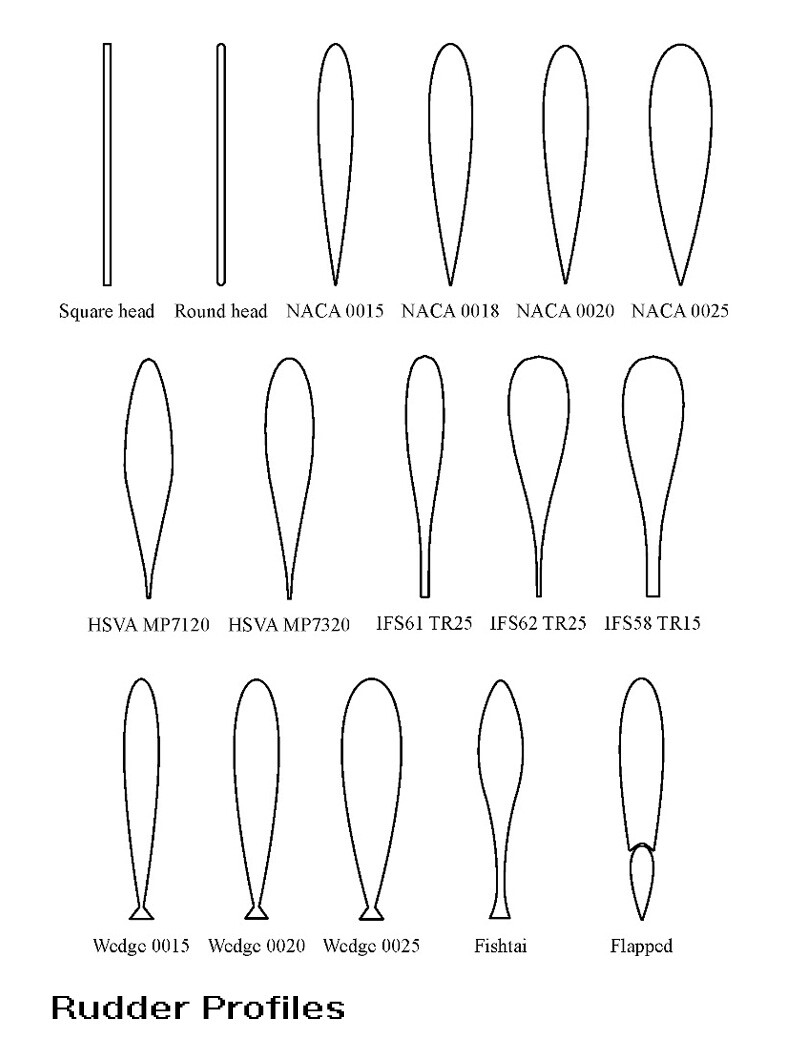

Rudder Profiles

Rudder’s designs are quietly similar to each other. The most common feature they share is the blade.

All rudders have blades. This blade provides lift and drag that steers the ship in her desired direction.

However, the rudder differs in their shape. This is noticeable when viewed from the top or bottom.

The rudder profile is the sectional shape of a rudder and it has effects on steering performance.

These are the most common rudder profiles that ships have today.

- Flat Plate – can be Round head or Square head.

- NACA – originally developed in the aeronautical industry. It stands for National Advisory Committee for Aeronautics.

- HSVA – developed by Hamburg Ship Model Basin. This design reduces cavitation through good pressure distribution. It stands for Hamburgische Schiffbau Versuchsanstalt GmbH.

- IFS – also initially made by Institute für Schiffbauin Hamburg, Germany. Mainly achieves a high maximum lift coefficient, steep lift curve, and large stall angle.

- Fishtail – also known as Schilling rudders. Similar to the previous profiles but with a concave part connecting the tail. Some advanced seagoing dredgers use rudders with this profile.

- Wedge tail – similar to fish tail profile but has a sharper concave point.

- Flapped – have movable flap extension.

What’s the rudder profile of your ship?

Parts of a Rudder

Here is a typical part of a rudder shown in the image below.

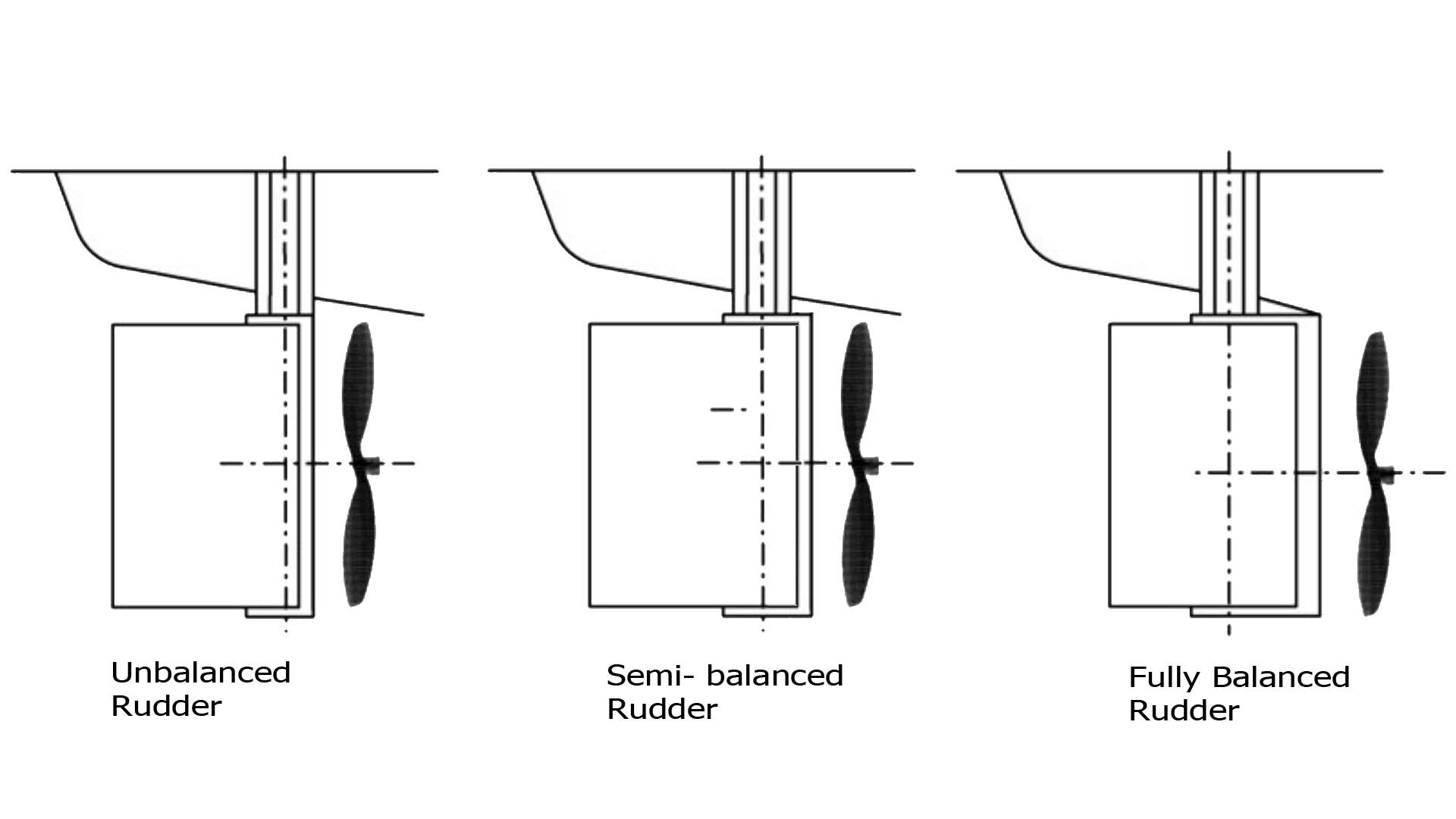

Balance Ratio

Conventional rudders are classified according to the position of the rudder stock in relation to the blade area.

This is called Balance Ratio and is a very important factor in determining the performance of a rudder.

The balance ratio compares the blade area forward of the hinge or rudder stock to the total area of the blade.

The main purpose of balancing the rudder is for the steering gear to achieve a reduction of turning torque when rudder angles are applied.

Types of Rudders

Selecting the right type of rudder for your ship is very important.

The maneuverability of the vessel highly correlates with the rudder profile, size, and model.

Economics must be duly considered since a vessel’s steering system has a direct impact on fuel consumption.

Lastly, rudders are constantly exposed to extreme forces. Making sure it is the right kind ensures less cavitation, less stalling, and a longer life span.

1. Unbalanced Rudder

This type of rudder has its entire blade area behind the rudder stock or axis of rotation. The leading edge, which is directly facing the propeller, is connected to the stock.

In an unbalanced rudder, the steering gear has to provide all the turning torque. The blade, on the other hand, is exposed to large bending moments.

Thus, unbalanced rudder is not widely used in modern ships but is popular among small vessels and fishing boats.

2. Semi-Balanced Rudder

Semi-balanced rudder has less than 20% of its blade area forward of the rudder stock.

The stock reduces the overall stress of the blade when water pressure is applied.

Since a portion of it is forward of the turning axis, this part counterbalances the force of water on the after part.

Modern ships commonly use semi-balanced rudder as part of their steering system.

3. Balanced Rudder

Also called a fully balanced rudder, this type has 20% to 40% of its blade area forward of the rudder stock.

Water pressure pressure striking on the forward part of the turning axis compensates the water force acting on the after part of the blade.

On some angles, it creates an equilibrium on the blade which makes the turning torque zero. This is the reason why we call them balanced rudders.

A balanced rudder is perfect for conducting evasive maneuvers when pirates are chasing you especially if you have no private maritime security on board.

With that setup, the steering gear system using a balanced rudder can be lighter and smaller.

Other Rudder Types

Other types of rudders use the conventional model of blade position in relation to its turning axis.

They are either balanced, semi-balanced, or unbalanced.

However, they differ in rudder profile, shape, and a few additional features.

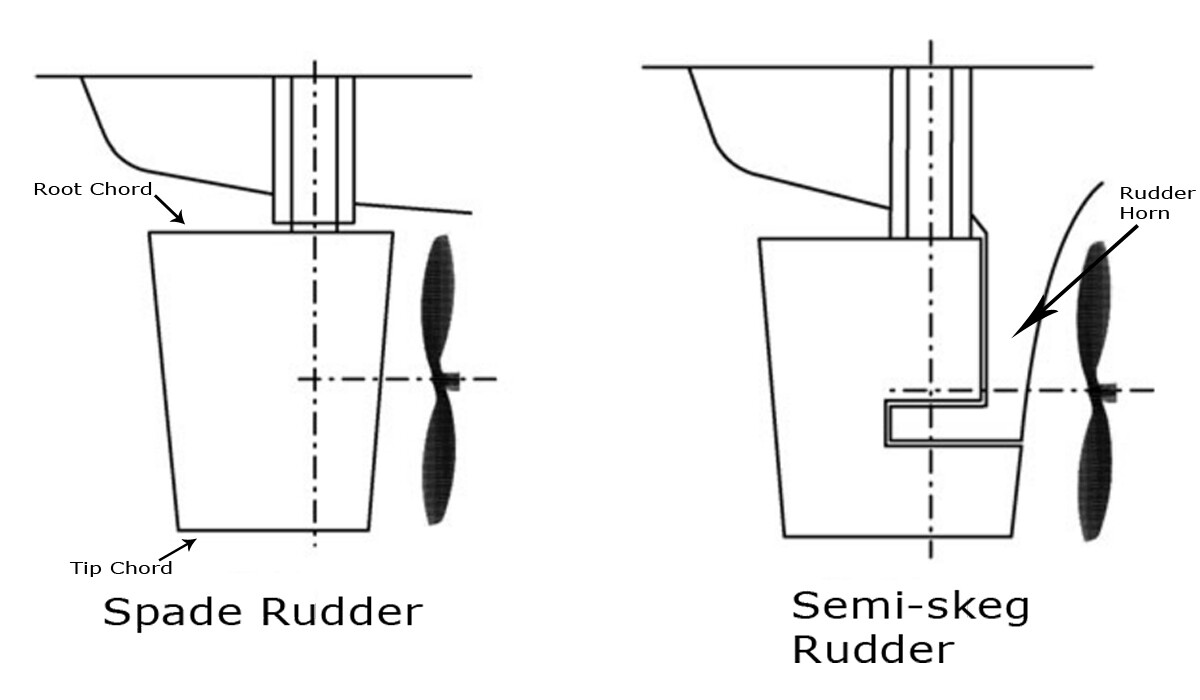

4. Spade Rudder

A spade rudder is a type of balanced rudder. The only differing factor is the shape of the blade.

The spade rudder’s blade is tapered starting from the root chord (top of the blade) and going to its tip chord (bottom of the blade).

Its taper ratio reduces drag and maximizes rudder force at high rudder angles.

6. Semi-skeg Rudder

Also known as a Horn rudder, a semi-skeg rudder is a semi-balanced rudder that employs a rudder horn forward of its stock.

Seafarers sometimes call them Mariner Rudder and we can see them on large oil tankers including VLCCs.

The horn is integrated into the ship’s construction providing structural support. This enables a larger rudder area possible.

Additionally, it has less turning torque than an unbalanced rudder and fewer bending moments than spade rudders.

6. Schilling Rudder

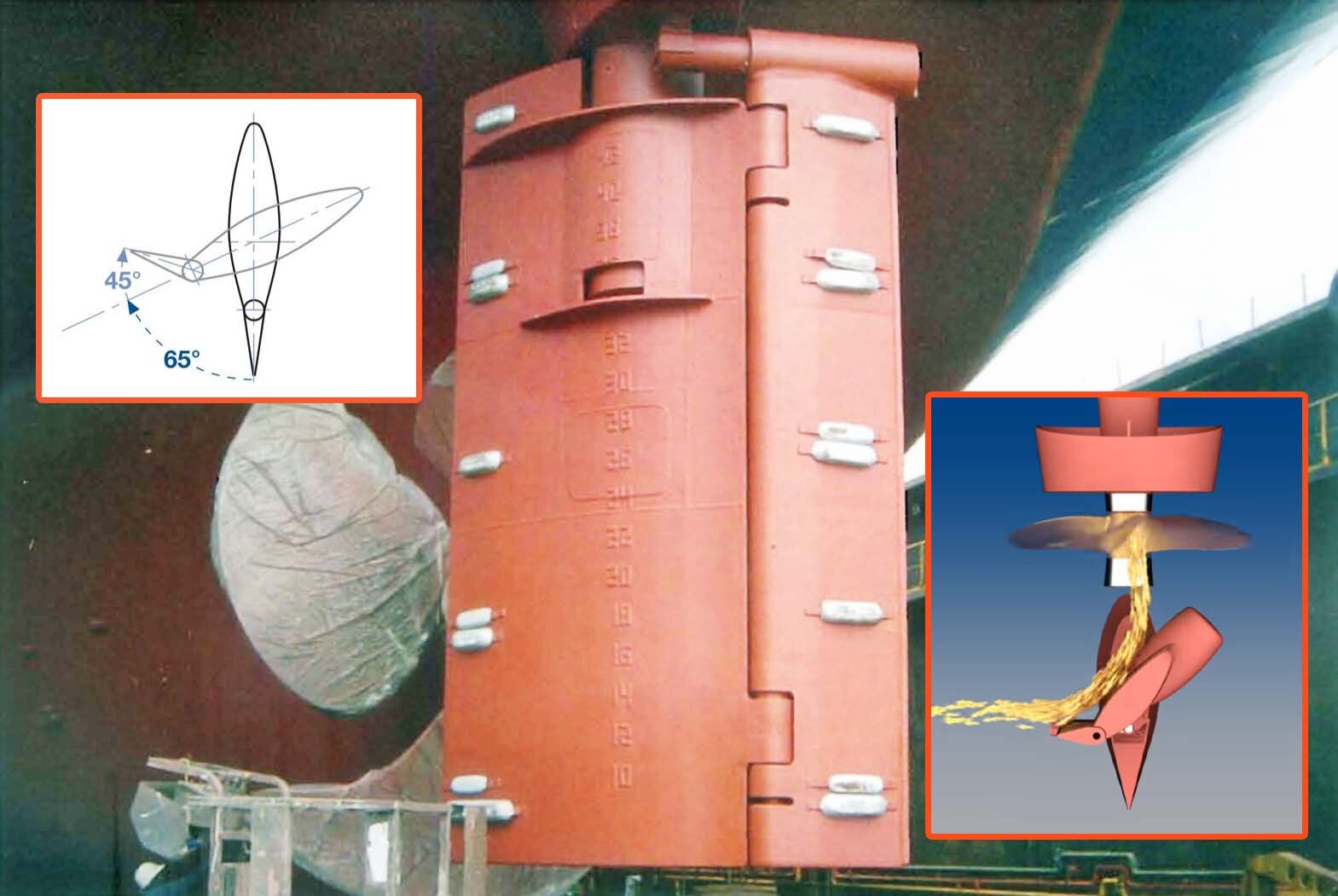

This rudder has a design profile similar to the Fishtail rudder except for the added end plates on the root and tip chord.

Even as a single-piece construction without moving parts, the Schilling rudder greatly reduces the turning circles of vessels.

Schilling rudder is perfect for ships having difficulty in their maneuverability, especially during slow steaming.

7. Becker Flap Rudder

Founded by German Captain Willi Becker, Becker Rudder became a revolutionary part of today’s steering system. Thus today, Becker Marine Systems holds its patent while developing them for better designs.

A Becker Rudder is a type of spade rudder that has a moving flap at the trailing edge.

The flap moves together with the main blade depending on the given rudder command.

Due to the versatility of its flap, Becker Rudder can reach more than 65° without worrying about stalling or rudder drag. This results in a smaller turning circle and cost-saving potential due to its efficiency.

I’ve seen this type of rudder in action. Even without a tugboat, vessels with a becker rudder can move laterally into jetties.

When I was in a tanker vessel, I saw it working like a stern thruster during maneuvering.

Today, there are many types of rudders on ships. They are a combination of the previous ones, especially their rudder profiles.

Some even have very similar build but differs on very few things.

What kind of rudder does your ship have?

May the winds be in your favor.

0 Comments