Pressure/vacuum (P/V) valves are essential safety devices on tanker ships. They are very important that no tanker vessel can operate without them installed.

When I was undergoing a basic tanker training course before coming on board, our instructor hammered into us the fundamental operation of PV valves.

It became clear to me how these “breathers” work after working on tanker ships and experiencing them in action, especially during loading operations.

Then we had an incident where the failure of these valves cost us a month in the shipyard and millions of euros in repair. But we were still lucky because nobody got hurt during the incident.

What are P/V Valves?

P/V Valves are part of a tanker ship’s primary venting device installed to avoid damage due to over or under-pressurization of cargo tanks.

In the most basic sense, these valves release excess pressure from inside the tank and vent it out into the atmosphere when there is too much pressure inside. During times of negative pressure, they also open up allowing the air inside the tank to avoid implosion.

This arrangement allows the tank to “breathe” during pressure variations. Hence, P/V valves are built on many oil and product tankers of various sizes.

It has many names like Pressure/ Vacuum Relief Valve, Pressure/ Vacuum Valve, or High Velocity Pressure/ Vacuum Valve.

P/V valves work automatically. They don’t require an electrical or pneumatic supply but function solely on calibrated pressure settings.

Since this piece of device has two primary functions, let’s discuss them here and their operation one by one.

Arrangements

Before a P/V valve is installed, it must satisfy a few regulations covered by IMO, SOLAS, or the class societies.

- The venting arrangements shall be so designed and operated as to ensure that neither pressure nor vacuum in cargo tanks shall exceed design parameters.

- Have as great a height as is practicable above the cargo tank deck to obtain maximum dispersal of flammable vapors, but in no case less than 2 meters above the cargo tank deck.

- Be arranged at the furthest distance practicable but not less than 5 meters from the nearest air intakes and openings to enclosed spaces containing a source of ignition and from deck machinery and equipment which may constitute an ignition hazard.

And by the way, anchor winches and windlass on the forward station are considered ignition hazards. P/V Valves on cargo tanks 1 wings are strategically installed to conform to these regulations.

When do P/V Valves trigger?

Three main conditions trigger P/V valves.

One is during cargo loading operations and this is something that you must watch out for because if they don’t function, you have to manually trigger it.

When the tank is filled with cargo, it displaces the inert gas inside. These gases must be released into the atmosphere while fulfilling the regulations. This is through pressure/ vacuum relief valves.

Another is during heavy rolling.

When the ship rolls heavily, the liquid cargo inside the tank moves violently. This creates a sudden pressure imbalance thereby triggering the P/V valves.

Lastly, the pressure/ vacuum relief valve triggers during a change of temperature.

When a ship travels to warm climates like, in the Middle East, liquid and gaseous volume inside the tank expands and must be released.

In contrast, when the ship travels to cold climates like Europe, the contents inside the tank shrink creating a vacuum. To avoid under pressure, the vacuum valve operates automatically.

Working Principle of P/V Valves

Cargo tanks undergo pressure changes at any stage of the voyage but are mostly pronounced during cargo operation.

If left unchecked, these pressure differentials could damage the cargo tank.

I experienced firsthand an over-pressurized tank due to failure of P/V valve operation. It cost the company around €3.5 million in repairs.

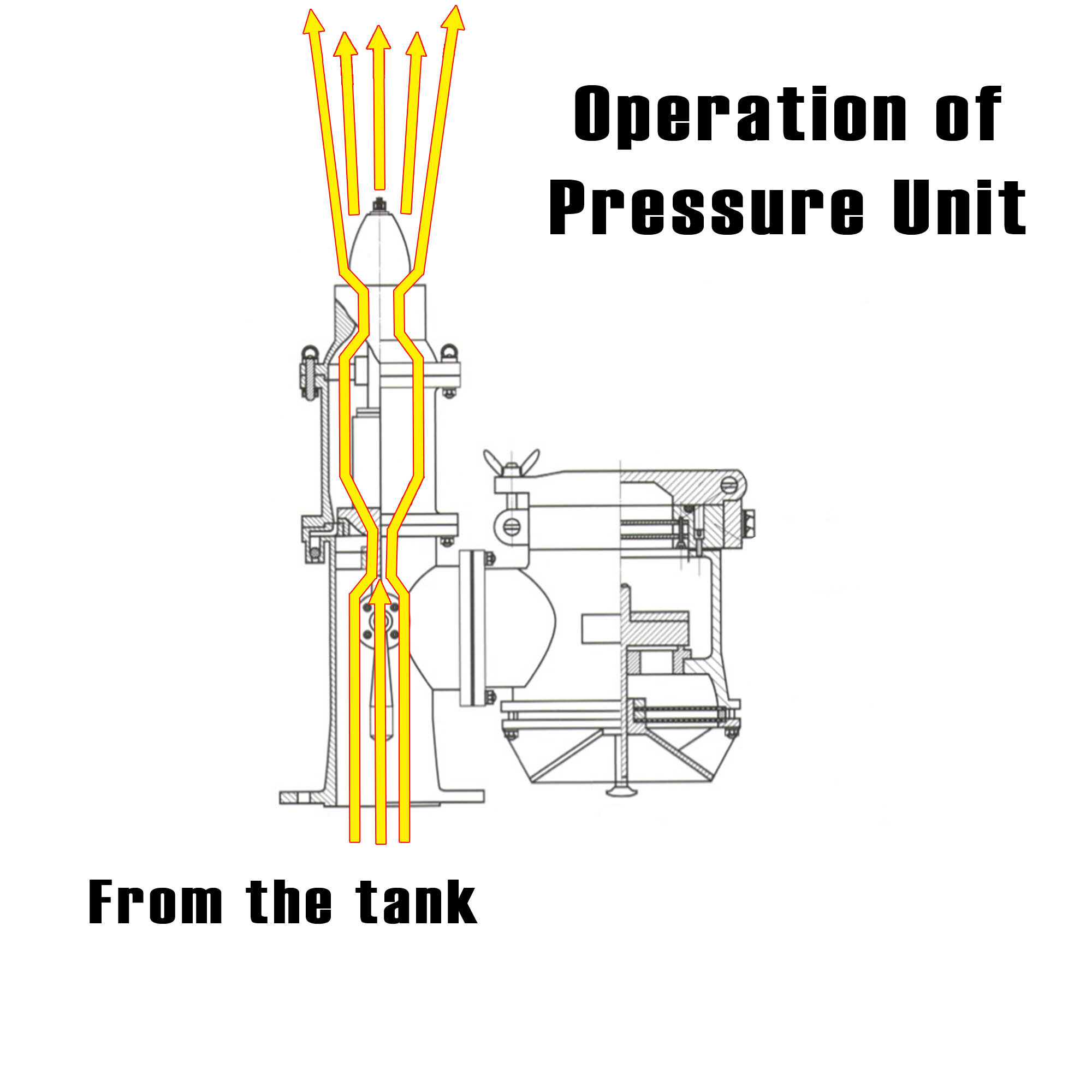

Pressure Unit

When the cargo tank is over-pressurized, the pressure unit of the P/V valve activates thereby releasing excess pressure from the tank.

These gases must go out somewhere or else the tank would explode. Here lies the function of the pressure unit.

It’s very easy to spot the pressure unit. It looks like a rocket and is found at the topmost part of High Velocity Pressure/ Vacuum Valve.

Pressure Settings

Normal positive pressure inside the tank is around 700 to 800 mmWG (millimeters of Water Gauge) or 0.0686 bars to 0.0785 bars.

The high-pressure setting for the pressure unit of a P/V valve is 1,400 mmWG or 0.1372931 bars.

Meanwhile, cargo tank design pressure is tested at 2,500 mmWG or 0.245 bars.

Vacuum Unit

Over-pressurization is not the only hazard that we should be concerned about.

Sometimes, the cargo tank’s pressure drops due to changes in temperature or heavy rolling. This is where the vacuum valve operates.

We do have to consider that vacuum valves should not be operated when discharging flammable cargoes. Instead of air, we must use inert gas in this case.

Vacuum Setting

The vacuum setting is at -250 mmWG or -0.0245 bars. Others are designed at -350 mmWG or -0.0343 bars.

The cargo tanks’ vacuum pressure setting is tested at -700 mmWG or -0.0686 bars.

Question: Why can’t we use one automatic valve for over and under-pressurization?

P/V valves’ pressure and vacuum unit are separate but coming from the same line.

During purging or inerting, I saw practices wherein the manual lifting handle of the pressure unit is tied to keep it open. This is common in tanker ships.

However, this is dangerous. Let me explain why.

P/V Valves Design

When the pressure valve activates, it shoots the gas out as high as it can.

The speed of gas coming out of it is around 30 meters per second (30m/s).

It mixes with oxygen in the atmosphere thereby forming a flammable mixture.

This should be a problem. However, the speed of fire when it catches a flammable gas mixture is around 10m/s.

In conclusion, whenever the flammable gas mixture shooting out of the P/V valve catches fire, it can not go inside the tank.

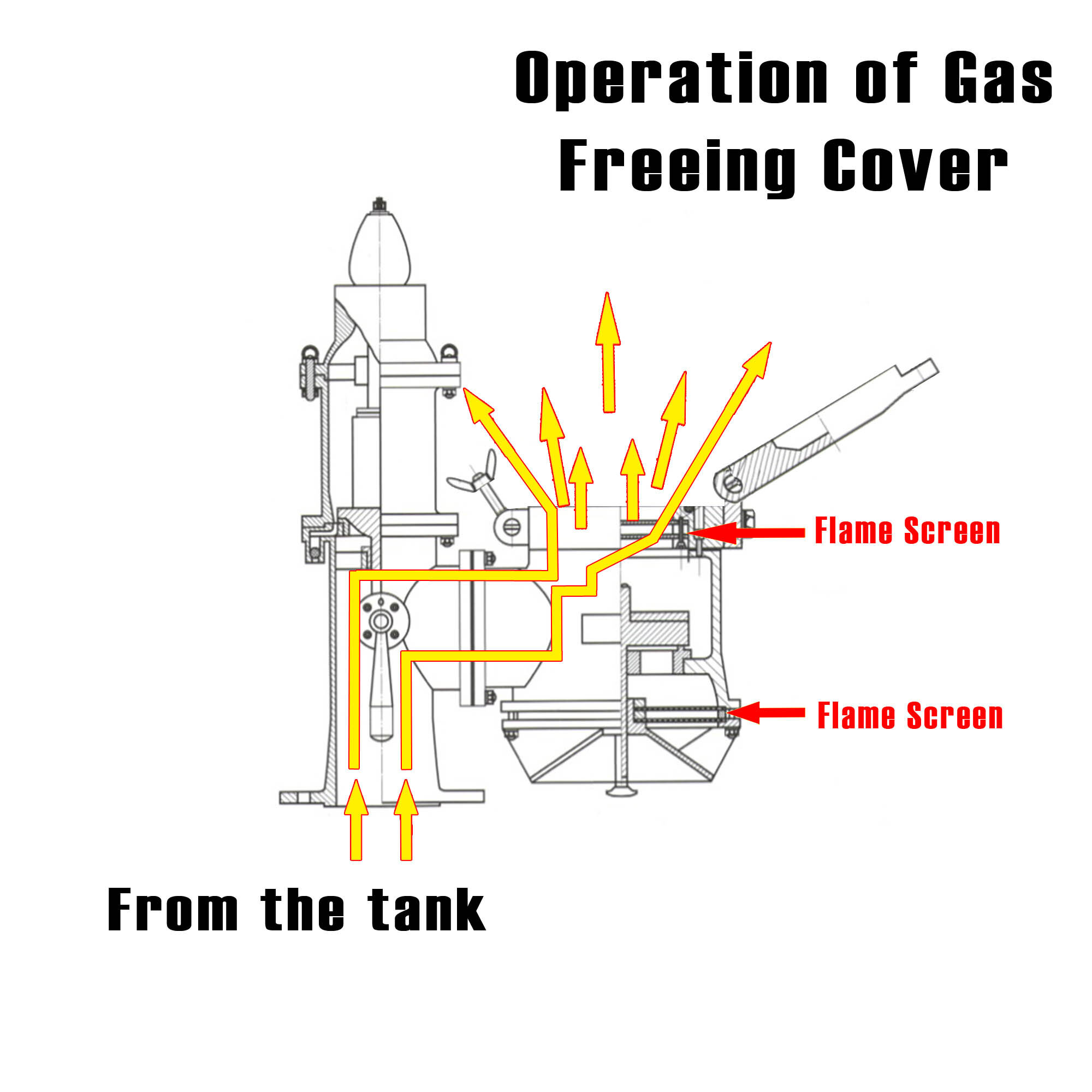

During under pressure, the vacuum unit activates thereby taking in air from the atmosphere. Fire can not go inside the tank even if it is being sucked due to the presence of a “flame screen”.

This is why the pressure and vacuum units are separated in a P/V valve.

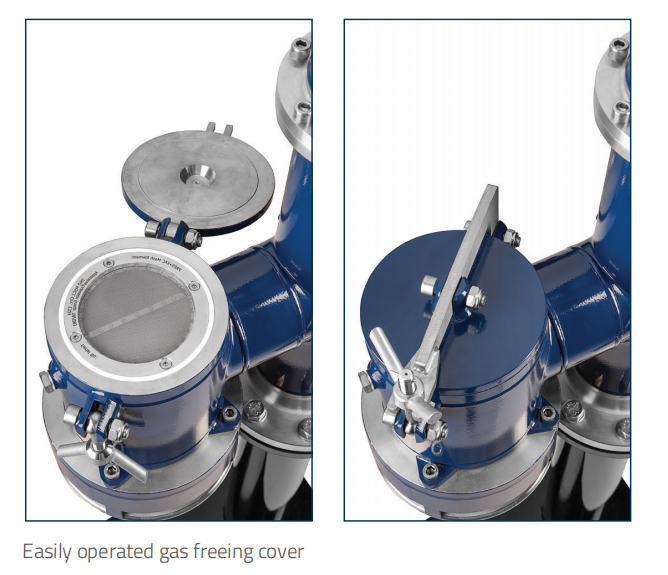

Gas Freeing Covers

There is though, a method for directly releasing gases to the atmosphere using one of the components of P/V valves.

This is through the use of gas-freeing covers.

Installed on top of the vacuum unit, the gas-freeing covers can be opened during purging or inerting.

It is positioned above the deck so the gas can be easily diluted into the atmosphere.

More importantly, it is equipped with a flame screen so it’s more safer than tying the pressure unit with a rope or using vapor locks.

What’s your experience with P/V valves?

May the winds be in your favor.

0 Comments