The inert gas system is one of the most critical components of a tanker vessel.

Vessels using inert gas in their tanks are enjoying the benefits of safe operation against fire and explosion.

No smoking on deck, no naked lights, intrinsically safe equipment only, and always following rules and regulations put tankers as one of the safest ships.

But the I.G. system takes us to a whole new level of safety. In fact, this equipment is a game changer!

This takes me to my cadetship where our vessel was not equipped with an I.G. system.

I thought it was normal and okay until our Captain explained to me the risk of not having one. After that explanation, I became very very careful on deck.

First off, let’s see some historical records stressing the importance of inert gas.

Accidents and Inert Gas (I.G.)

Sixteen years ago, a group of investigators reviewed 35 incidents involving fire and explosions on tanker ships’ cargo deck areas.

In a report that followed, it was noted that most explosions happened during tank cleaning and gas-freeing operations.

A lot of them occurred inside the cargo tank where the tank atmosphere was not monitored.

But the profound case they discovered was that none of the accidents happened during the operation of inert gas!

What is an Inert Gas System (IGS)

Going back to our training days, an I.G. system is a component in an oil or product tanker that produces an I.G.

An Inert Gas System (IGS) is a crucial safety feature onboard tanker vessels, especially those transporting flammable or hazardous liquid cargoes.

Its primary purpose is to create and maintain a safe atmosphere inside cargo tanks and other enclosed spaces to prevent the risk of fire and explosion.

The IGS accomplishes this by reducing the oxygen content within these spaces to a level where combustion is impossible.

It does so by replacing the normal air (which contains about 21% oxygen) with inert gases, typically nitrogen (N2) and carbon dioxide (CO2).

The reduced oxygen levels create an inert or non-combustible environment, making it extremely challenging for a fire to ignite or for flammable substances to reach their ignition temperature.

What is an Inert Gas?

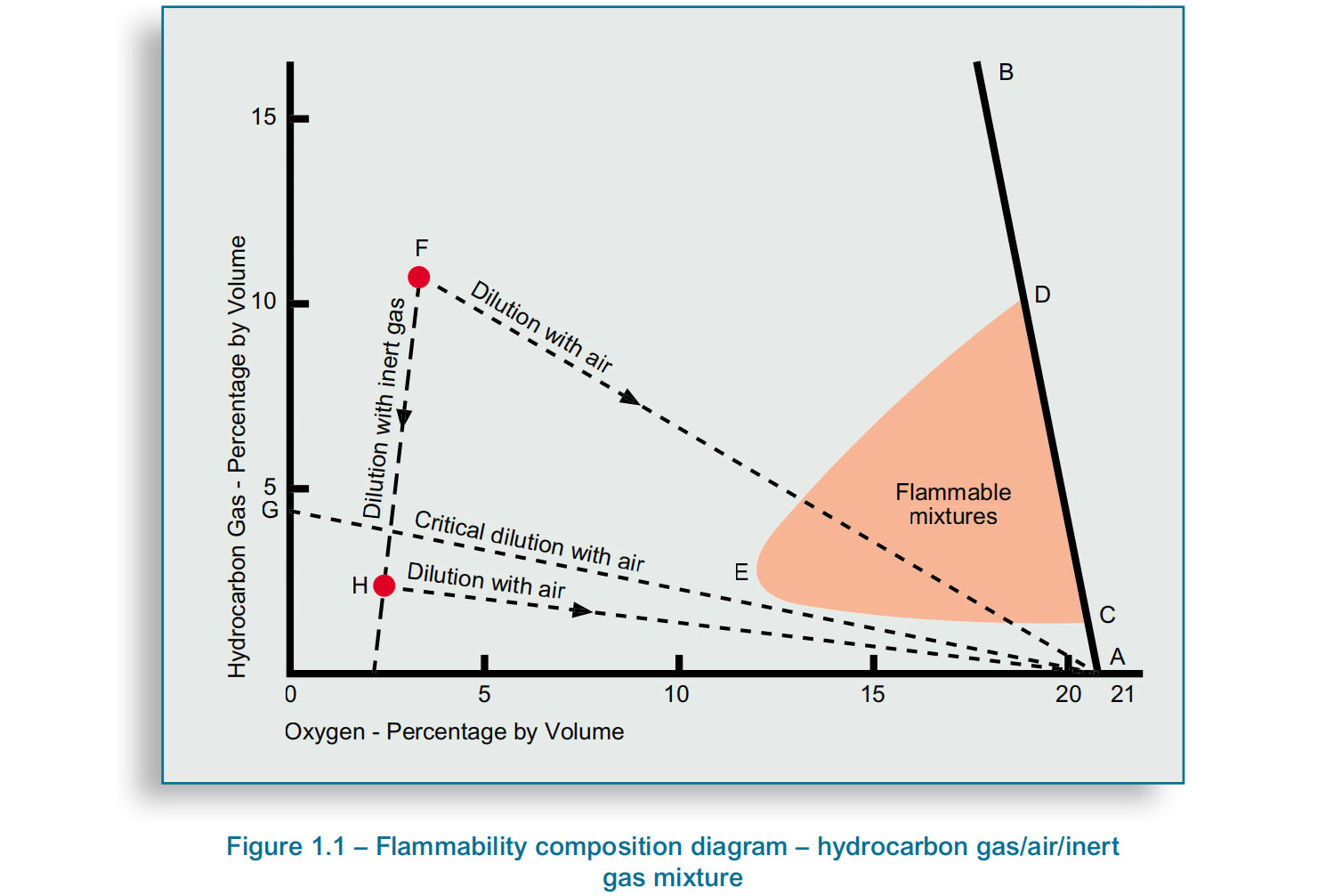

In the context of tanker ships, an inert gas is a mixture of gas that contains very little amount of oxygen, so little that it doesn’t support combustion.

It is primarily used on oil and chemical tankers to create a safe atmosphere inside cargo tanks and to prevent explosions.

Around 12% of oxygen is needed for a hydrocarbon gas to burn or continue burning.

Here lies its importance. It lowers the oxygen content inside the tanks to make combustion or explosion not possible.

Regulation states that a tanker should be inerted to 8% oxygen by volume. However, that level is reduced to 5% for port regulations.

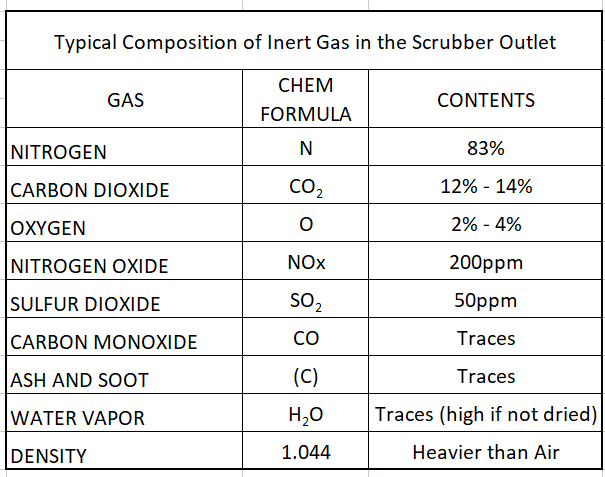

Composition of Inert Gas

The contents of this gas vary depending on the type of I.G. Plant and the regulations behind it.

Basically, Nitrogen and Carbon Dioxide make up its main components.

In some cases, Argon is used.

Here below are the typical components of this gas.

- Nitrogen (N2) – 83%

- Carbon Dioxide (CO2) – 12% to 14%

- Oxygen (O2) – 2% to 4%

- Nitrogen Oxide (NOx) – 200ppm

- Sulfur Dioxide (SO2) – 50ppm

- Carbon Monoxide (CO) – trace amounts

- Ash and Soot © – trace amounts

- Water Vapor (H2O) – trace amounts

- Density (1.044) – heavier than air

With oxygen at 2% minimum, this means that you can’t go lower than that.

Reaching close to that amount is also time-consuming and you may have to make your I.G. Plant work harder and longer.

On some models, they are able to produce an I.G. with 1% to 2% Oxygen levels. Thus, the figures may change depending on the manufacturer.

If you notice after ventilating a tank filled with I.G., the bulkheads and heating coils may have black carbon deposits clinging to them.

These are the ashes and soot from the I.G. plant. And that is one reason why they say that an inert gas is dirty.

Three Sources of Inert Gas

Inert gas can be generated in any of the following machinery on board.

- Uptake gas from the ship’s main or auxiliary.

- An independent Inert Gas Generator (I.G. Plant).

- A gas turbine plant equipped with an afterburner.

I.G. System Terminologies

Before digging in further, let us discuss first a few definitions involving the use of IG.

Inert Condition – an atmospheric condition in the tank to which the oxygen has been reduced to 8% or less by volume by the addition of inert gas.

Inerting – means the introduction of I.G. into a tank with the object of attaining the inert condition.

Inert Gas Plant – means all equipment specially fitted to supply, cool, clean, pressurize, monitor, and control delivery of I.G. to cargo tank systems.

Inert Gas System – means an I.G. plant and I.G. distribution system together with means for preventing backflow of cargo gases to the machinery spaces, fixed and portable measuring instruments, and control devices. In essence, this is the I.G. plant and distribution system.

Inert Gas Distribution System – means all piping, valves, and associated fittings to distribute inert gas from the I.G. plant to cargo tanks, vent gases to the atmosphere, and protect tanks against excessive pressure or vacuum.

Purging – means the introduction of I.G. into a tank already in the inert condition with the object of:

- further reducing the existing oxygen content; and/or

- reducing the existing hydrocarbon gas content to a level below which combustion cannot be supported if air is subsequently introduced into the tank.

Topping up – means the introduction of I.G. into a tank that is already in inert condition with the object of raising the tank pressure to prevent any ingress of air.

How I.G. is Delivered on Deck

1. An I.G. generator creates an inert gas by burning its fuel. The combustion burns the air so that the remaining oxygen is reduced to the required level.

2. We now have an I.G. which is still a bit dirty. Before it reaches the cargo tanks, it is first cooled, refined, and filtered to remove excessive soot and water vapor.

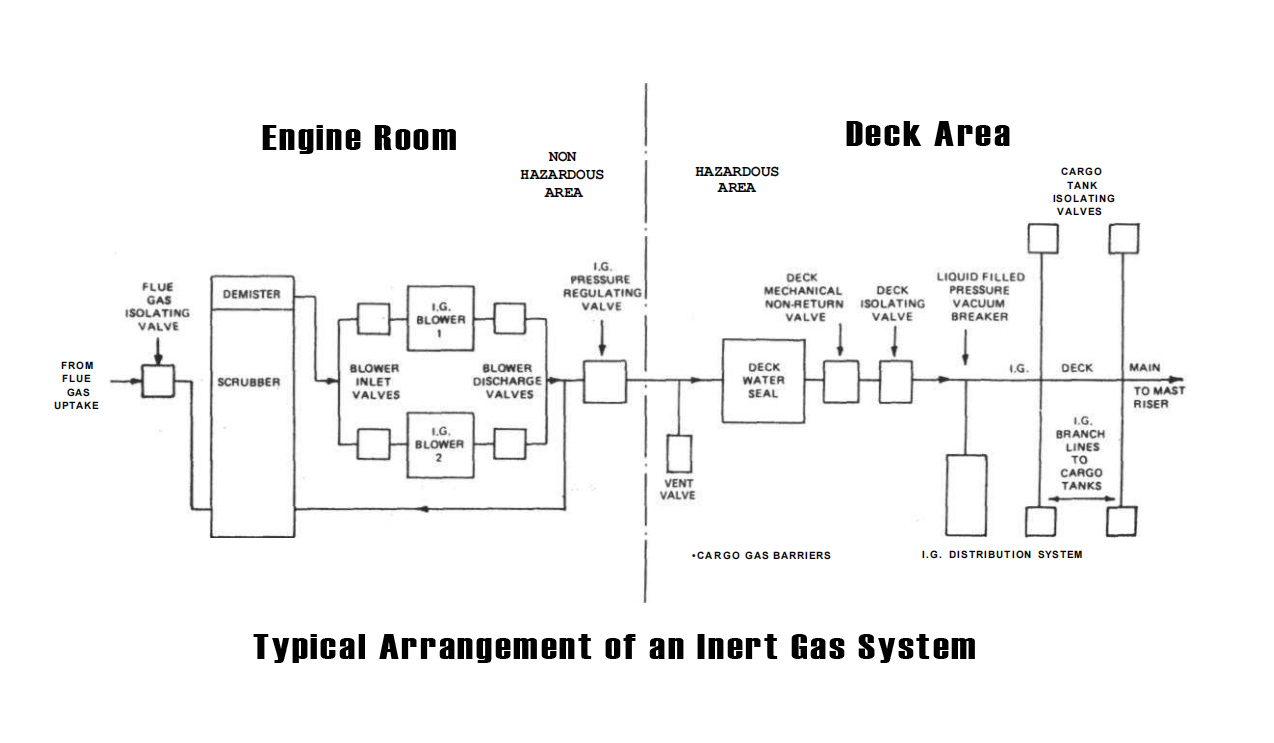

3. The gas passes into a scrubber and demisters to purify it. Two blowers push these gases into the distribution system until it reaches the cargo tanks. Check out the inert gas system diagram below.

4. The OOW in the CCR monitors the gases including its rate of flow. An alarm sounds off whenever its oxygen content falls above 8%.

5. Before the I.G. goes into the cargo tanks, it passes into a Deck Water Seal, also known as a deck seal. Here, the gas is “washed”. At the same time, the deck seal prevents the backflow of hydrocarbon gases from the cargo tanks into entering the engine room.

6. Some safety devices are installed to prevent over-pressure and under-pressure inside the tanks.

Inert Gas System System Diagram

This diagram shows the schematic layout of the I.G. System (IGS) both in the Engine Room side where the I.G. is produced, and the Deck Area where it is distributed into individual tanks.

Operations Requiring the Use of Inert Gas

As we discussed at the beginning of this article, inert gas plays an important role in safe operations on board.

Hydrocarbons that are present in our cargoes are very flammable. Here are deck operations where inert gas is required.

1. Discharging Operation

When a tanker is discharging her cargo, the pressure inside her tank becomes negative.

This negative pressure triggers the vacuum valve of our P/V valves to suck in air to avoid the implosion of our tanks.

However, introducing fresh air inside our tanks poses the risk of fire and explosion.

Instead of fresh air, inert gas is introduced at 125% of the cargo discharge rate to keep the tank in positive pressure.

2. Tank Cleaning Operation

The cargo tanks should be washed in an inert condition while keeping the pressure inside the tank positive.

This is where I.G. is used.

There is also a build-up of static electricity inside the tank as high-pressure tank cleaning is utilized to take out the remaining cargo residue.

If the tank is not inerted, an explosion could occur.

3. Purging Prior to Gas Freeing

Whenever a cargo tank needs to be inspected, it must attain a gas-free condition.

This means that the atmosphere inside the tank should have 20.9% oxygen by volume, 0% LEL, and toxic gases below the Threshold Limit Value or TLV.

To accomplish this, air is introduced. But before pumping air inside cargo tanks, its hydrocarbon gas must be reduced to avoid a flammable mixture.

Purging the tank with this gas achieves this goal.

4. Prior Entering Port

Port facilities require that the oxygen level inside the tank be less than 8%.

Thus, purging the tank or topping it up with inert gas enables the ship to avoid heavy fines or denial of port entry.

Methods of Inert Gas Introduction into the Tanks

There are three main ways that inert gas is introduced into tanks especially if the tank is in a gas-free condition.

Knowing which method enables us to understand the readings we receive when checking for the tank atmosphere.

Moreover, each method offers a variety of choices to the seafarer as to which one works best on that particular ship.

1. Dilution Method

This is a mixing process of inert gas and the current gas inside the tank.

I.G. has been introduced into the tank at high velocity. It then mixes inside forming a homogeneous mixture.

This mixture exits outside the tank via purging pipe thereby lowering the oxygen content inside the tank over time.

2. Displacement Method

This method works in a process by which the inert gas being introduced into the tank displaces the current gases inside.

It is done slowly so as not to mix the I.G. with the gases inside.

The inlet of I.G. and the outlet of the purged gases are located in opposite directions.

If you introduce it from the aft topside of the tank, the outlet of purged gases should be on the forward bottom part.

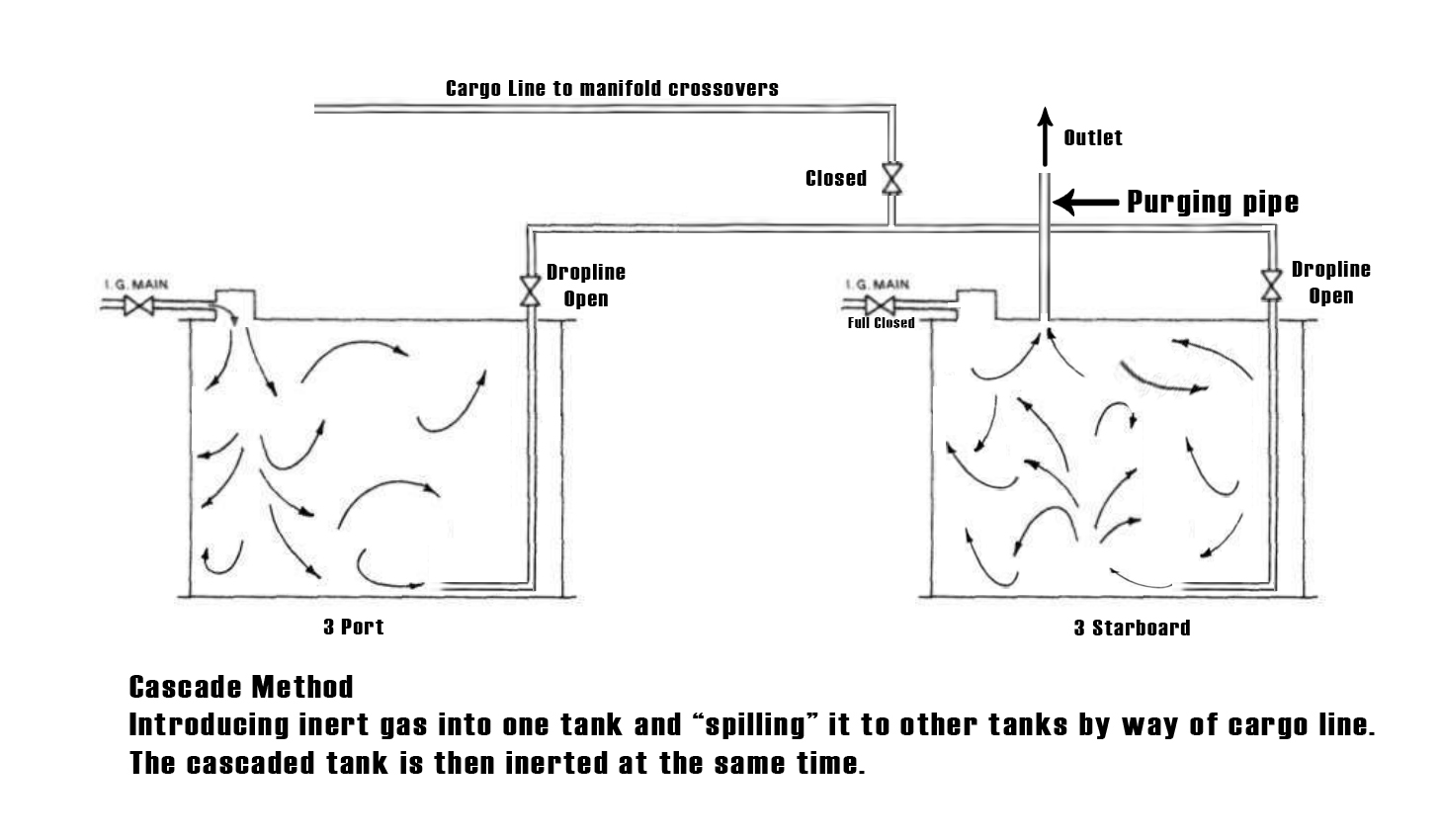

3. Cascading Method

The third method uses either of the two above but takes it even further.

Instead of releasing the purged gas directly into the atmosphere, it is transferred to another tank by means of a cargo piping system.

This means that you are also purging that tank together with the ones where you introduced the inert gas.

Precautions

Inert gas is an asphyxiant. You could die or suffer brain damage if exposed at long intervals.

During any inerting operation on deck, it is best to keep away and stay inside the accommodation.

Lock all water-tight doors and recirculate the air to avoid taking I.G. in your blower intakes.

If for some reason you need to get out, you must call the bridge, inform OOW, and bring a radio with you.

Have a safe operation on board and

May the winds be in your favor.

0 Comments