Dredging is the process of extracting or removing sediments and other materials under bodies of water and transporting them to another location using different types of dredgers.

Extracted deposits from seabed include silt, sand, soil, trash, mud, gravel, debris, and marine organisms.

Dredgers are not hard to find once spotted. You can even check their latest projects using free vessel tracking websites.

Dredging can also be conducted on land. But since seafarers can’t relate to that, let’s focus on dredgers operating in rivers, lakes, canals, channels, estuaries, and harbors.

What are Dredgers?

Dredgers are watercraft that carry out dredging.

They have various designs depending on their capability, purpose, and method of extraction.

Some companies build ships for the sole task of dredging. They have built-in power and can move on their own, even sailing from one port to another.

But there are also other dredgers on land. Examples of these are excavators or cranes with a clamshell bucket.

To be used on the waters, dredger owners place them on top of a self-propelled barge or barge towed by a tugboat to be able to conduct dredging in bodies of water.

Why Dredge?

There are many reasons why we carry out dredging. Most of the time, the main and most common objective is to deepen certain parts of rivers, harbors, canals, or seas.

Before a port or canal is created, the area has to be dredged so huge ships can enter and leave safely.

Natural sedimentation crops up waterways thereby endangering vessels against grounding or touching bottom. Maintenance dredging solves this problem.

We can also assign dredgers to create trenches for submarine pipelines underwater.

Additionally, companies use them to “dig holes” for foundational support of structures built on top of water such as bridges and windmills.

Mining and Recovery

Another reason for dredging is to gather minerals from underwater much like mining does. Corporations usually carry this venture.

People also use dredging to recover priceless materials blanketed in sediments underwater.

Think about the valuable things sunken ships carried with them a long time ago. Sediments would have crept on top of these precious items due to undersea currents and siltation.

Some construction materials like gravel and sand can be found underwater. Recovering them through dredging is a known method.

Dredging also maintains the ecosystem by removing trash and debris as well as restoring shorelines to their former glory.

Types of Dredgers

We usually categorize dredgers according to the methods used in extracting dirt from underwater and delivering it up to the surface.

There are two main types of dredgers. However, there is a third type reserved for those that don’t fall on either of the two.

1. Mechanical Dredgers

In the most basic explanation, mechanical dredging involves the use of grabs or buckets.

It “scoops” up the sediments and delivers them up for disposal.

In many cases, mechanical dredging prides itself on mobility and precision. It is robust as it is able to remove rock, gravel, and other “cohesive” materials.

This is why they are mostly used in harbors, rivers, channels, and canals.

Mechanical dredgers are further classified according to their build.

a. Grab/ Clamshell Dredger

When it comes to precise dredging, a Grab or clamshell dredger does the job.

They are basically clamshell cranes redefined for dredging and then installed on a barge.

The grab suspends with a wire, lowered into the seabed, and excavates the sediments once it touches them.

Due to that mechanism, it has the advantage of dredging on deep spots with pinpoint accuracy. They can work with clay, gravel, and even broken rocks but are not particularly effective in fine silts.

The operator then hauls up the excavated material and discharges it in a separate barge or hopper.

We will talk about hoppers later on.

b. Dipper Dredgers

These types of dredgers are very similar to a Backhoe dredger. The only difference is the position of the bucket.

Remember how a shovel works? You thrust the blade into the ground in a forward motion in order to take out the soil.

A Dipper Dredger works in a similar principle. It is a backhoe mounted on a barge and gathers dirt through forward thrust.

To help stabilize the barge, there are spuds on its forward and aft parts. These spuds moor the barge by standing on the seabed.

Companies use Dipper Dredger when the water ahead is too shallow for the barge to float.

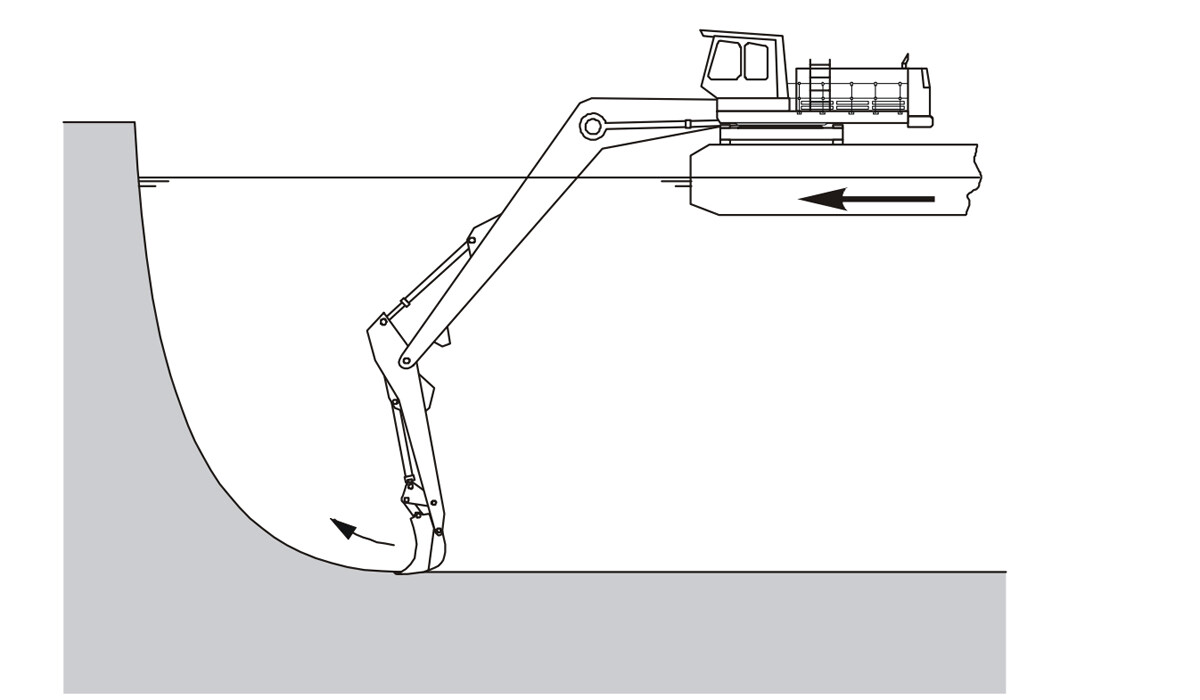

c. Backhoe Dredger

Backhoe Dredgers (BHD) are basically hydraulic excavators land but slightly modified to do dredging works.

They are mounted on a barge and work similar to Dipper Dredger except for the method it scoops up sediments.

While Dipper Dredger gathers seabed through forward thrusts, Backhoe Dredger collects them through backward movement.

A transport barge is also moored alongside the dredger where the sediments are accumulated before being disposed of elsewhere.

d. Bucket/ Bucket Ladder Dredger

Just like the types of merchant ships, naming dredgers can be straightforward too.

Bucket ladder dredgers are composed of two primary things which set them apart from other dredgers.

They have, well, buckets, and a ladder.

This machine has a series of buckets installed around a chain in an endless loop.

These buckets rotate in one direction and go up on a ladder. They scoop up sediments upon reaching the bottom of the seabed and bring it on top.

Before rotating back downward, the sediments fall off a chute which goes to a barge for disposal.

2. Hydraulic Dredgers

Aside from grabs, buckets, or scoops, some use pumps, and pipelines to extract sediments from underwater to the surface.

We call these types Hydraulic Dredgers. They come in many forms but share a common principle.

Hydraulic dredgers use suction to bring the dredged sediments up. Think of it like a vacuum cleaner operating underwater.

Loosened sediments mixed with water enable sucking them out possible. Hence, they work best in cohesion-less soils like sand, silt, or even gravel.

Hydraulic Dredgers are sometimes called Suction Dredgers.

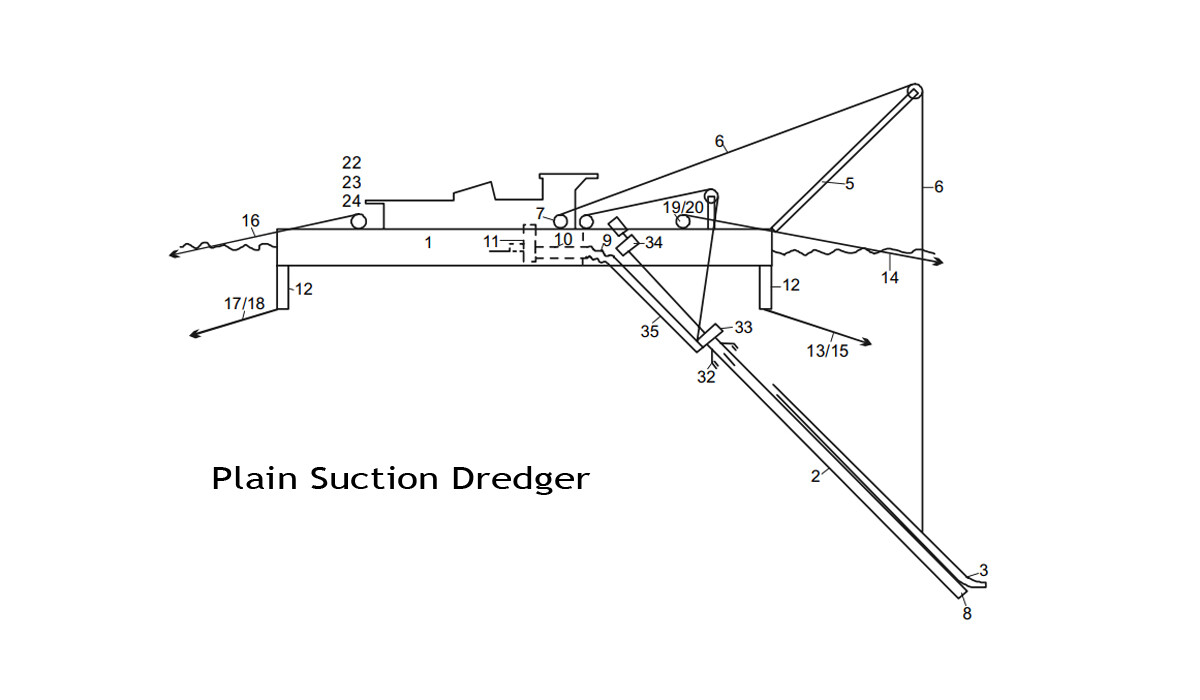

a. Plain Suction Dredger (PSD)

It is called PSD for very simple reasons- it only consists of suction pipes, pumps, and discharge pipes. These components are installed in a barge or pontoon.

The vessel is kept stationary through the use of spuds. In some scenarios, complex mooring is involved.

During operation, the suction pipe is lowered to the bottom using wires. It sucks the sediments while releasing a water jet.

This disturbs the soil thereby creating suspension for easy pumping.

The discharged material is transferred to a barge. Or it is pumped directly to the disposal area using extended pipelines fitted with booster pumps along the way.

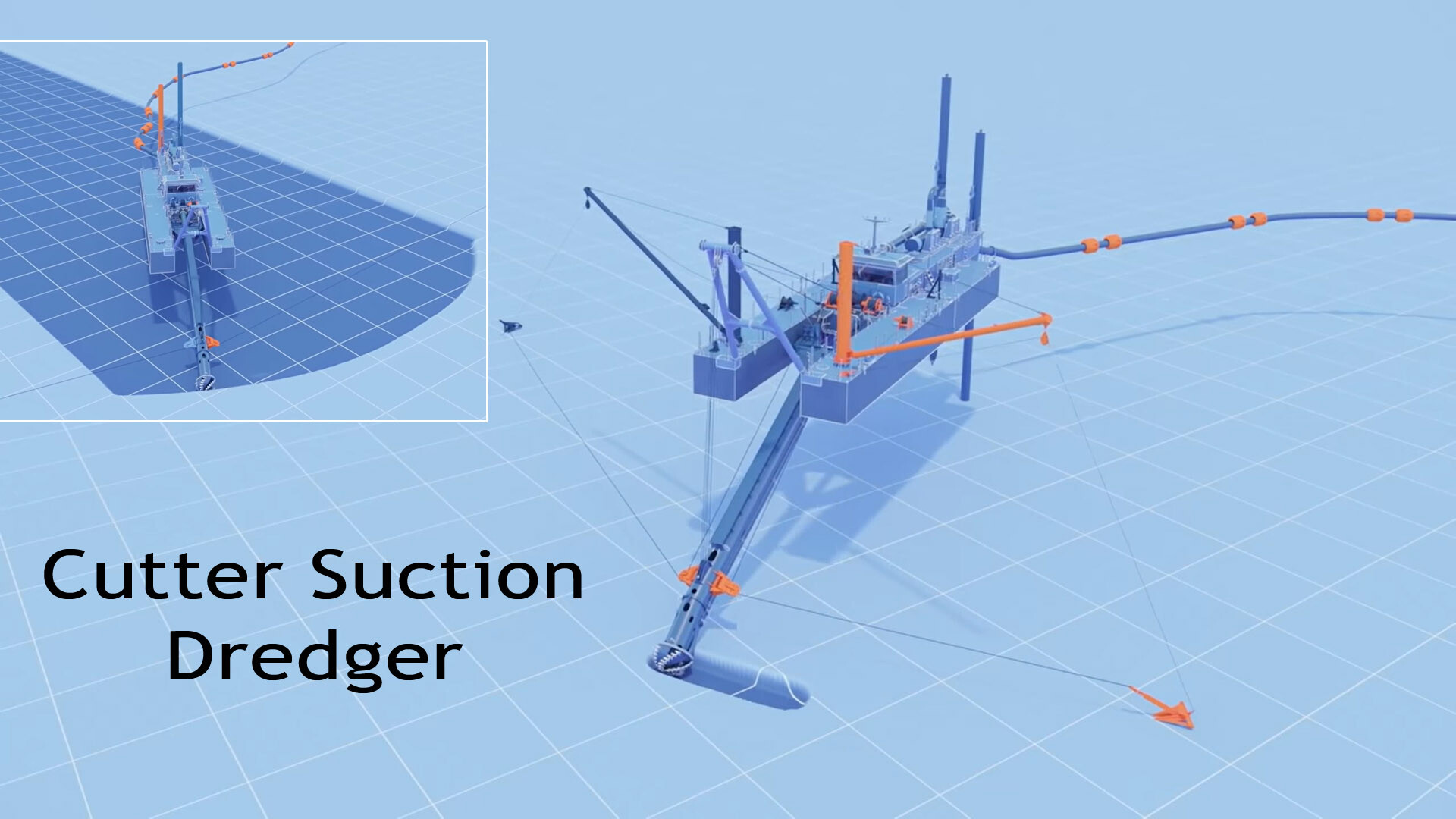

b. Cutter Suction Dredger

In some instances, sediments harden over time making PSD less effective. This is where Cutter Suction Dredger (CSD) comes in.

CSD is similar to PSD but differs from what’s on the tip of its suction pipe.

It uses a rotating cutter to excavate the material thereby loosening them for easy pumping.

The disturbed sediments are discharged to a barge or directly to the disposal site using pipelines similar to PSD.

Cutter Suction Dredgers use spuds to keep them in position. Aside from that, it lowers its anchors on the port and starboard side.

CSDs use these anchors for swinging the ship with the pivot point being the stud. This type of dredging covers huge areas while keeping the depth at a uniform level.

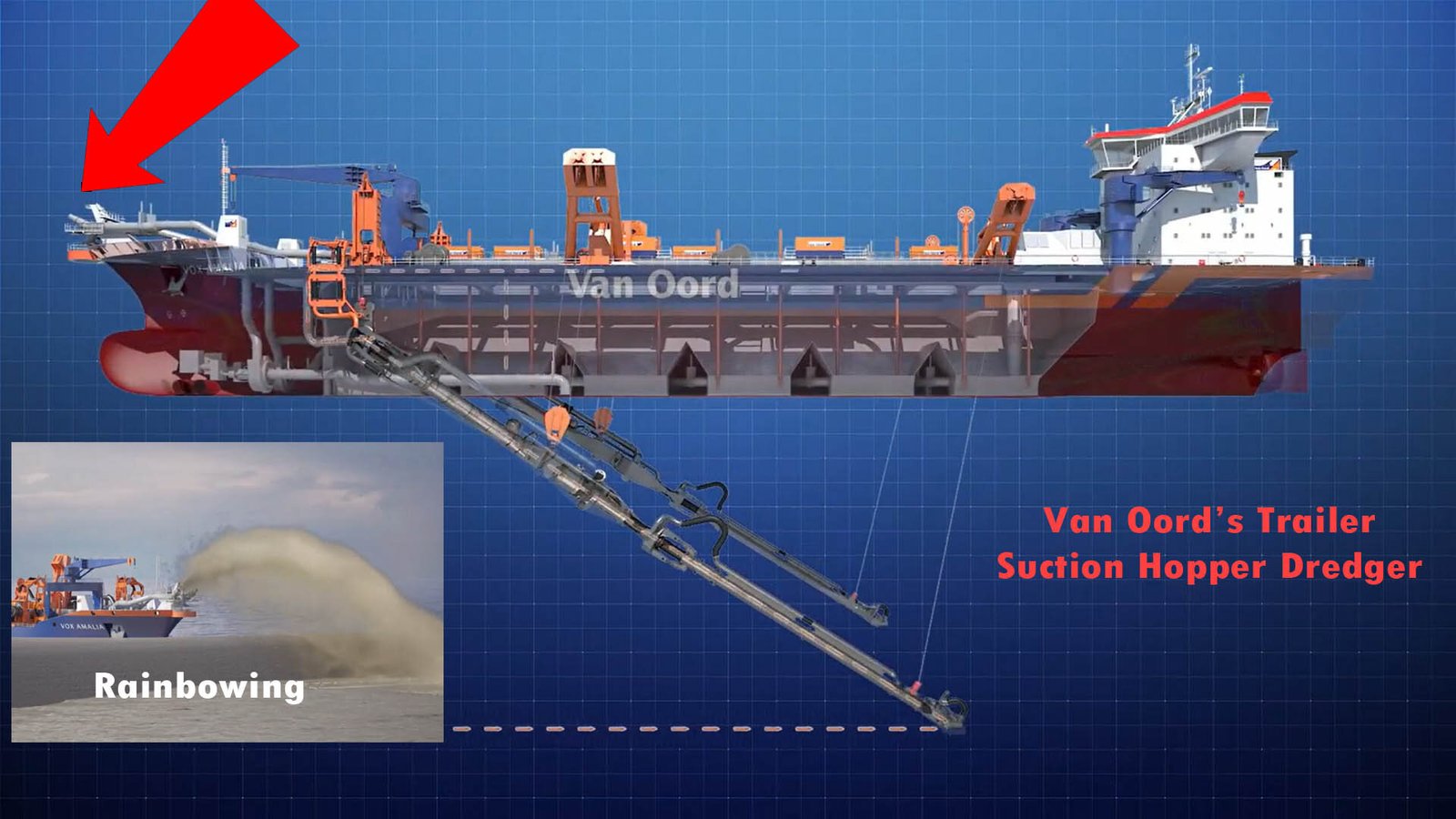

c. Trailing Suction Hopper Dredger

We mentioned “hopper” at the beginning of this article. Here, it has its own meaning.

Hoppers are containers for bulk materials like trash, rocks, silt, sediments, sand, or grain. This is similar to the cargo spaces of tankers and bulk carriers except for one difference.

Its main feature is the opening bottom doors as its discharge mechanism.

A Trailing Suction Hopper Dredger (TSHD) is a capable, self-powered seagoing vessel equipped with hopper-type cargo holds. Thus, you can find seafarers working on this type.

TSHD doesn’t use spuds or requires a barge for discharging. It slowly navigates or “trails” in a pre-determined route.

After lowering its trailer arm on its side, it slowly moves forward while sucking down the material along the way.

The dredged soil can be dealt with in three ways.

- Stored in the hopper and disposed in a designated area

- Connected to a pipe leading to the discharged site

- “Rainbowing”

Rainbowing is spraying out the dredged material to the discharge location.

3. Other Types

Other types of dredgers can not be classified between mechanical and hydraulic due to their special characteristics and working mechanisms.

Generally, these types are small in comparison to the two. And these dredgers also have small production output. They are suitable for ponds, lakes, and rivers.

Due to their size, we can transport these ships using trucks and haul them in and out of the water with a crane and sometimes by itself.

Some of these dredgers are unmanned and not suitable for seafarers since these types are used in small-scale dredging.

a. Auger Suction Dredger (ASD)

Auger Suction Dredger operates on the same principle as a Cutter Suction Dredger (CSD). The two differ on what’s in their suction head.

While CSD uses circular rotating blades to dredge the bottom, ASD operates with a horizontal screw blade called Archimedean Screw.

Archimedean Screw works in a way that when it rotates, the sediments are guided to the middle where the suction head is attached.

The ship dredges as it moves forward. Its dredging pattern is like plowing a field compared to CSD’s swinging pattern.

b. Jet-Lift Dredgers

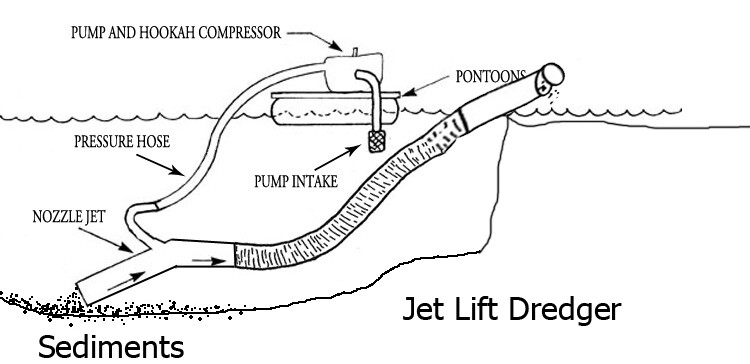

This type of dredger doesn’t use a pump to directly suck the water-sediment mixture. It uses the Venturi Effect much like how educators work.

The suction head has no moving parts. Streams of water going at high speed pull out the surrounding water together with sediments around it.

This is only used in small-scale dredging activity.

c. Air Lift Dredgers

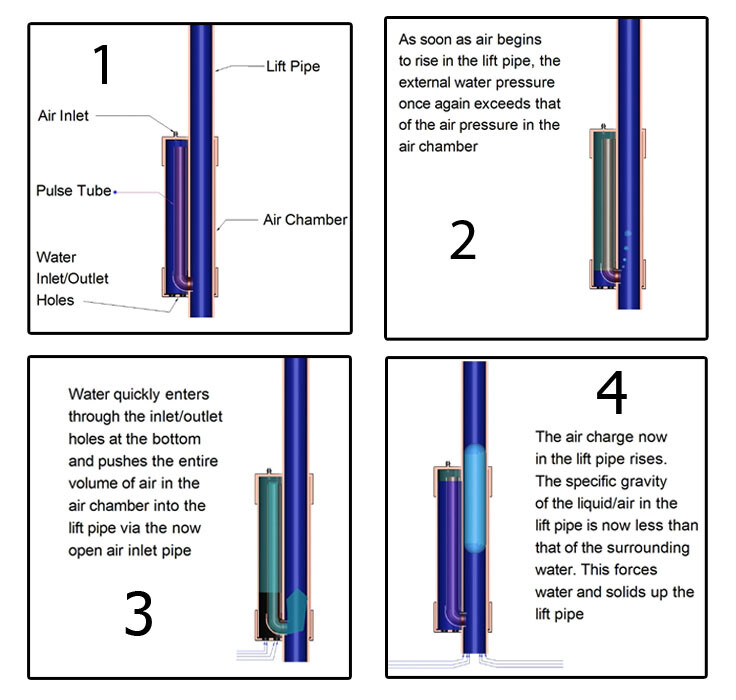

This type of dredger works in a similar way to a Jet Lift Dredger. It has two main components; a Pulse tube and a Lift Pipe.

A pulse tube is where high-pressure air is introduced at pulsating intervals between 1 second to three seconds.

The compressed air travels to the Lift Pipe while displacing the water.

As soon as the air inside the lift pipe bubbles up to the water surface, it draws in a water-sediment mixture.

The cycle repeats during the dredging process.

d. Amphibious Dredgers

By the name itself, these types of dredgers are capable of operating on land and water.

They are basically heavy machinery excavators fitted with studs, floaters, or legs that enable them to “walk, stand or float”.

These types work predominantly on rivers, lakes, swamps, or ponds.

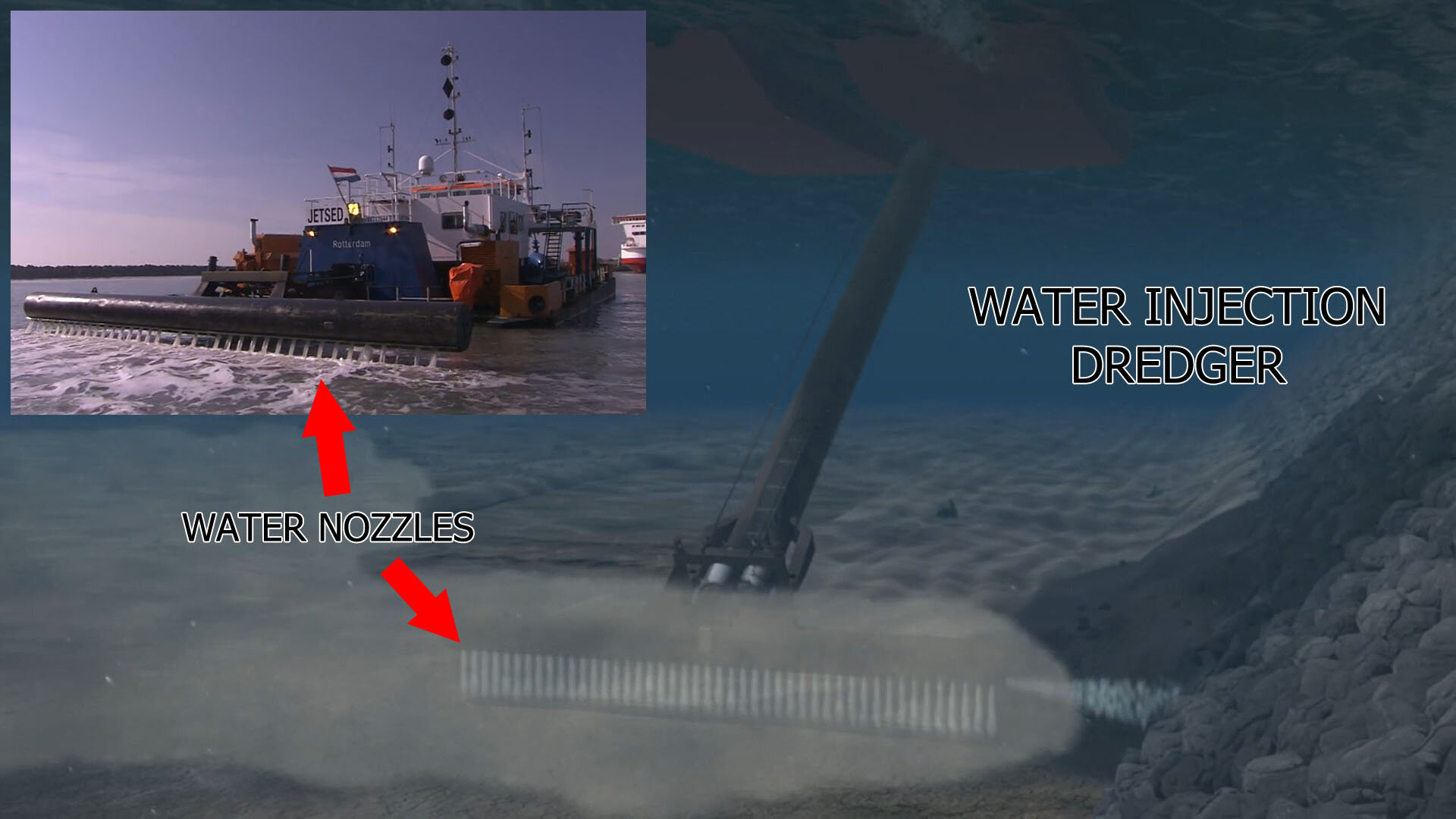

e. Water Injection Dredger

When we talk about dredgers, what usually comes to mind is a mechanism that picks up something from the seafloor and brings it up to the surface.

Water Injection Dredger (WID) is an outlier as it functions very differently.

Instead of grabs or suction pumps, this dredger does not pick up sediments for disposal.

This is how it operates.

It lowers a horizontal jet bar with a series of nozzles to the sediment layer and beams volumes of low-pressure water.

This “disturbs” the soil and creates fluidized sediments which creeps up horizontally away from the dredged area into the lower part of the water column.

The slope of the sea bed, hydrostatic difference, and tidal currents drive this phenomenon.

Hence, operators also call Water Injection Dredging, “Natural Dredging”.

Would you like to work on a dredger? Which shipping companies hire crew for dredger vessels?

May the winds be in your favor.

0 Comments